Reception, storage, picking, dispatch… The warehouse is in full swing every day. And everything has to be under control: time, flow, stock, quality. A single mistake and the whole chain slows down. Without optimised organisation, chaos can quickly ensue. How can you keep things running smoothly and efficiently? Take a look at a day in the life of a warehouse.

The different stages of a day in the warehouse

06 :15 am 🕔 Start of the day and goods receipts

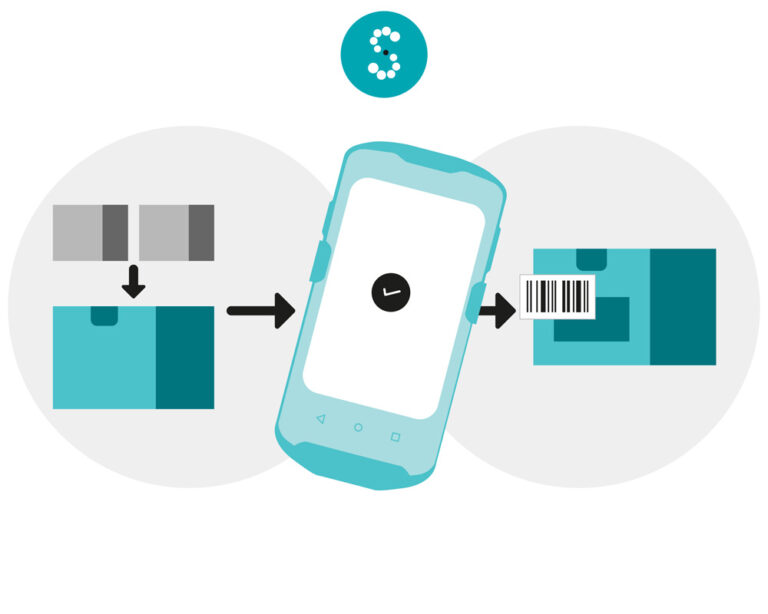

The trucks arrive at dawn. Teams unload, scan and check each pallet to make sure it matches the order.

❌ A common problem. Manually checking each reference takes time and increases the risk of errors.

✅ With a WMS like Satelix Logistics. A simple scan automatically registers products in stock, reducing inventory discrepancies and speeding up receiving.

08 :15 am 🕘 Storage and organisation, a key stage in the warehouse

Teams store goods in the right places. Optimised organisation facilitates picking and reduces unnecessary movements.

❌ A common problem. Lack of strategy makes it difficult to locate products and slows down order picking.

✅ With Satelix Logistics. The software allocates optimal locations according to picking frequency and item volume. Every product remains accessible in a matter of seconds.

11 :15 am 🕚 Order picking, a key moment in the warehouse

The first orders arrive. The pickers collect the items, pack them and send them off.

❌ A common problem. Operators spend too much time looking for products and risk making picking errors.

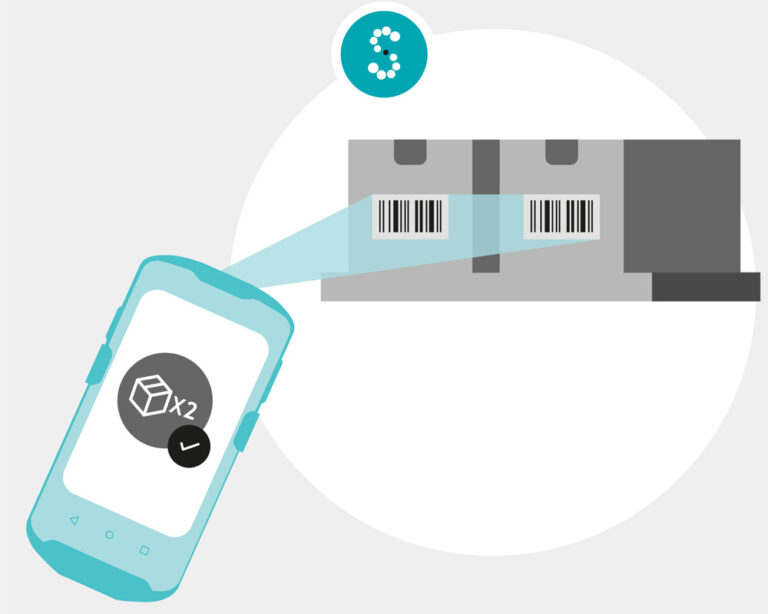

✅ With Satelix Logistics. The WMS guides pickers with an optimised route. Result: fewer trips, faster picking and zero errors thanks to validation scanning.

2 :30 pm 🕞 Checking and packing to ensure the safety of every shipment

Our teams check every order before it is dispatched. Rigorous preparation guarantees compliant delivery.

❌ A common problem. A poorly prepared or labelled parcel leads to delays and customer returns.

✅ With Satelix Logistics. The WMS checks each parcel before dispatch. It automatically generates carrier labels and ensures full traceability.

4 :30 pm 🕓 Shipping, the last storage of a day in the warehouse

Parcels are loaded onto trucks according to their destination and priority. Every movement is recorded in real time to ensure accurate tracking.

❌ Common problem. Lack of control before dispatch leads to delivery errors and uncontrolled delays.

✅ With Satelix Logistics. A final scan validates each shipment, guaranteeing reliable tracking and error-free delivery.

Improve your day-to-day warehouse operation with a WMS

Control the 3 main flows in a warehouse: suppliers, stock and customers.

From receiving items to consulting them. From inventories to transfer movements. From replenishment to stock removal. From preparation to dispatch… The Satelix Logistics WMS is your ally for optimised days!

Pssss 🤫 We’ve listed the 10 most common stock management mistakes. To find out more, click here.